2023. 8. 23. 10:21ㆍ엔지니어링

https://www.seas.upenn.edu/~nanosop/PECVD_Recipes.htm

PECVD_Recipes

PECVD Recipes Updated on 10/9/2014 Note: Since the process is carried out at high temperature, some outgas or vaporized species out of a dirty wafer may affect the quality of the deposited film. So, make sure that the wafer-as-received is cleaned with Acet

www.seas.upenn.edu

PECVD Recipes

Updated on 10/9/2014

Note: Since the process is carried out at high temperature, some outgas or vaporized species out of a dirty wafer may affect the quality of the deposited film. So, make sure that the wafer-as-received is cleaned with Acetone and IPA (or Methanol) using ultrasonicator for each 3~5 min before use.

Contents

1 SiO2

2 Si3N4

3 a-Si (deposited on PECVD SiO2)

1. SiO2

1.1 Default recipe

- T = 350 ºC

- 10%SiH4/He = 50 sccm

- N2O = 710 sccm

- N2 = 90 sccm

- Pressure = 1,000 mTorr

- RF = 20 W

- Refractive index = 1.462 at 632.8 nm (updated on 9/12/2012)

- Literature value = 1.457 at 632.8 nm [1]

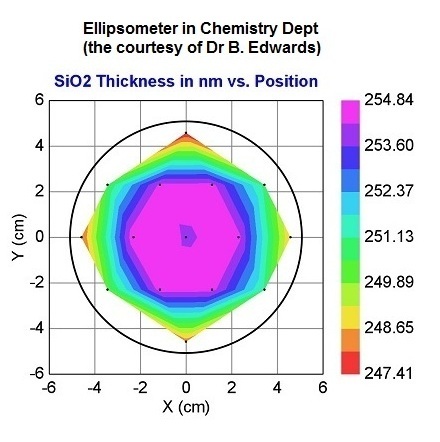

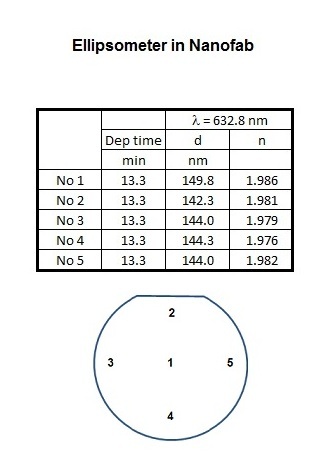

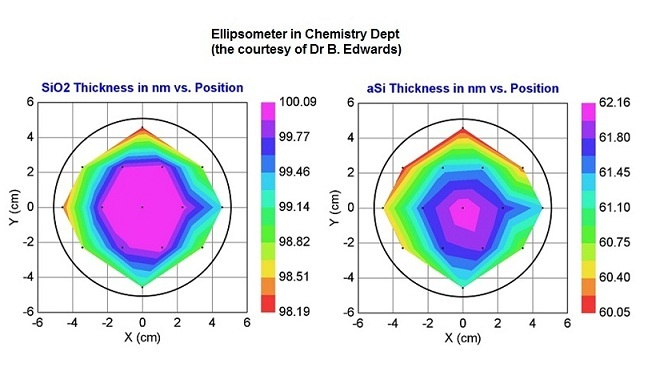

1.2 Comparison with other tool

2. Si3N4

2.1 Default recipe

- T = 350 ºC

- 10%SiH4/He = 170 sccm

- NH3 = 20 sccm

- N2 = 820 sccm

- Pressure = 1,000 mTorr

- RF = 20 W (13 sec)

- LF = 20 W (7 sec)

- Refractive index = 1.981 at 632.8 nm (updated on 9/12/2012)

- Literature value = 2.023 at 632.8 nm [2]

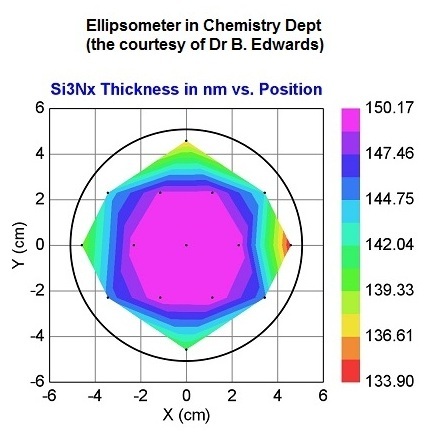

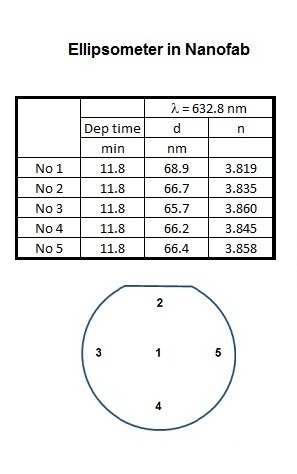

2.2 Comparison with other tool

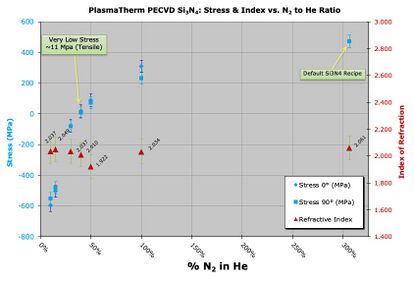

2.3 High stress films

- updated on 10/7/2013

- Prepared by Chia-Hsing Pi

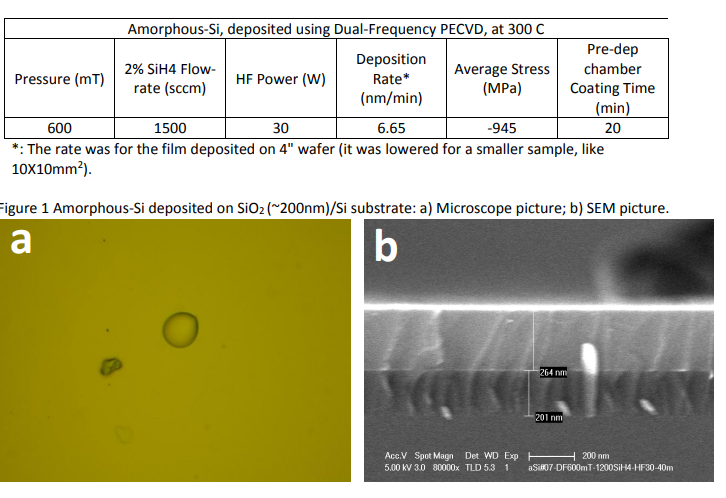

3. a-Si (deposited on PECVD SiO2)

3.1 Default recipe

- T = 250 ºC

- 10%SiH4/He = 500 sccm

- Pressure = 1,000 mTorr

- RF = 8 W

- Deposition rate = 5.7 nm/min (updated on 9/21/2012)

- Refractive index = 3.843 (updated on 9/21/2012)

- Literature value = 4.500 at 632.8 nm [3]

3.2 Comparison with other tool

- a-Si on 100 nm thick SiO2 layer on Si wafer

* 추가로 퍼니스 타입 공정에는 온도가 650도 정도 순수 실란 플로우로 조건 확인 한 경우가 있음

https://wiki.nanofab.ucsb.edu/wiki/images/9/9d/03-Amorphous-Si-PECVD-2.pdf

https://wiki.nanofab.ucsb.edu/wiki/PECVD_Recipes

PECVD Recipes - UCSB Nanofab Wiki

wiki.nanofab.ucsb.edu

PECVD Recipes

Back to Vacuum Deposition Recipes.

Contents

- 1PECVD 1 (PlasmaTherm 790)

- 2PECVD 2 (Advanced Vacuum)

- 3ICP-PECVD (Unaxis VLR)

PECVD 1 (PlasmaTherm 790)

PECVD 1 Process Control Plots - Plots of all process control data

SiO2 deposition (PECVD #1)

- SiO2 [PECVD 1] Current Process Control Data

- SiO2 [PECVD 1] Historical Data - Oct. 2021 and earlier

SiN deposition (PECVD #1)

- Si3N4 [PECVD 1] Standard Recipe

- Si3N4 [PECVD 1] Current Process Control Data

- Si3N4 [PECVD 1] Historical Data - Oct. 2021 and earlier

Low Stress Si3N4 (PECVD#1)

- Low Stress Si3N4 [PECVD 1] Standard Recipe

- Low Stress Si3N4 [PECVD 1] Historical Data - 2021-10 and earlier

SiOxNy deposition (PECVD #1)

- SiOxNy Standard Recipe

- SiOxNy Data 2014 - Rate, Index etc.

- SiOxNy1000A Thickness uniformity 2014

Standard Cleaning Procedure (PECVD #1)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. )

- Load the recipe for cleaning "CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning.

| SiO2 | TBD |

| Si3N4 | TBD |

| SiOxNy | Same as XYZ |

Standard Cleaning Recipe (PECVD#1): "CF4/O2 Clean"

Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that it will pop up a window for the cleaning time upon running the recipe - you do not need to edit the recipe before running it.

PECVD 2 (Advanced Vacuum)

PECVD 2 Process Control Plots - Plots of all process control data

SiO2 deposition (PECVD #2)

- SiO2 [PECVD 2] Standard Recipe - "STD SiO2"

- SiO2 [PECVD 2] Current Process Control Data

- SiO2 [PECVD 2] Historical Data - Before Oct. 2021

SiN deposition (PECVD #2)

- Si3N4 [PECVD 2] Standard Recipe - "Nitride2"

- Si3N4 [PECVD 2] Current Process Control Data

- Si3N4 [PECVD 2] Historical Data - Before Oct. 2021

Low-Stress SiN deposition (PECVD #2)

Low-Stress Silicon Nitride, Si3N4 (< ±100 MPa)

- Low Stress Si3N4 [PECVD 2] Standard Recipe - "LSNitride2

- Low Stress Si3N4 [PECVD 2] Current Process Control Data

- Plots of Low-Stress Si3N4 Process Control Data

- Low Stress Si3N4 [PECVD 2] Historical Data - Before Oct. 2021Old Versions of the recipe:LS Nitride2 Standard Recipe 2014-5/9/2018STD LSNitride2 5/9/2018

Amorphous-Si deposition (PECVD #2)

Standard Cleaning Procedure (PECVD #2)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- (If >29min dep time) Wet cleaning: Start cleaning by using a cleanroom wipe sprayed with DI. Wipe upper chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA & wiping again.

- Load the recipe for cleaning "STD CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding required time for cleaning.

Standard Clean Recipe (PECVD#2): "STD CF4/O2 Clean"

Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that it will pop up a window for the cleaning time upon running the recipe - you do not need to edit the recipe before running it.

Clean Times (PECVD#2)

| SiO2 | 1 min. clean for every 1 min. deposition |

| Si3N4 | 1 min. clean for every 7 min of deposition |

| If > 29min total dep time(Season + Dep) | Wet Clean the Upper Lid/ChamberDI water then Isopropyl Alcohol on chamber wall & portholes |

ICP-PECVD (Unaxis VLR)

2020-02: New recipes have been characterized for low particulate count and repeatability. Only staff-supplied recipes are allowed in the tool. Please follow the new procedures to ensure low particle counts in the chamber.

The system currently has Deuterated Silane (SiD4) installed - identical to the regular Silicon precursor SiH4, except that it significantly lowers optical absorption in the near-infrared due to shifted molecular vibrations/molecular weights. This gas is more expensive and thus more applicable to optical application than to general-purpose SiN films.

Process Control Data (Unaxis ICP-PECVD)

- ICP-PECVD Process Control Plots - Plots of all Process Control data

- Low Deposition Rate SiO2

- High Deposition Rate SiO2

- Si3N4

- Low Stress Si3N4

Low Deposition Rate SiO2 [ICP-PECVD]

- Low Deposition Rate SiO2 [ICP-PECVD] - Standard Recipe - "SiO2 LDR250C"

- Low Deposition Rate SiO2 [ICP-PECVD] - Process Control Data

- Low Deposition Rate SiO2 [ICP-PECVD] - Historical Data - before Oct. 2021

High Deposition Rate SiO2 [ICP-PECVD]

- High Deposition Rate SiO2 [ICP-PECVD] - Standard Recipe - "SiO2 HDR250C"

- High Deposition Rate SiO2 [ICP-PECVD] - Current Process Control Data

- High Deposition Rate SiO2 [ICP-PECVD] - Historical Data

Si3N4 [ICP-PECVD]

- Si3N4 [ICP-PECVD] - Standard Recipe - "SiN 250C"

- Si3N4 [ICP-PECVD] - Current Process Control Data

- Si3N4 [ICP-PECVD] - Historical Data - before Oct. 2021

Low Stress Si3N4 [ICP-PECVD]

- Low Stress Si3N4 [ICP-PECVD] - Standard Recipe - "SiN Low Stress 250C"

Standard Cleaning Procedure [ICP-PECVD]

You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the Operating Procedure on the Unaxis Tool Page for details.

- SiNx etches at 20nm/min

- SiO2 etches at 40nm/min

Standard Clean Recipe

To Be Added

General Recipe Notes (Unaxis VLR ICP-PECVD)

- RF1 = Bias

- RF2 = ICP Power

- All recipes start with an Argon pre-clean with 0W bias (gentle), to improve adhesion/nucleation.

- Maximum SiO2 Dep. thickness allowed: 800nm

- Above this thickness, you must run a chamber clean/season before depositing more onto your product wafer.

'엔지니어링' 카테고리의 다른 글

| 클러스터 시스템 반송로봇 참고 매뉴얼 제이씨솔루션 제품 (0) | 2023.08.25 |

|---|---|

| RKC PZ400 온도컨트롤러 사용 방법 (0) | 2023.08.18 |

| 진공게이지 참고 AGC 302 (0) | 2023.07.27 |